Supervision: Univ.-Prof. Dipl.-Ing. Dr. Bernhard Zagar

The company Wimtec Sanitärprodukte GmbH, opens an external URL in a new window develops and sells high-quality touchlessly controlled sanitary systems.

As part of a doctoral thesis and in collaboration with WimTec, DI Leonhard Haslinger, is developing methods for capacitive position sensing and recognition of hand and finger gestures. The results of this work should be used for further development of touchlessly controlled sanitary installations.

In terms of capacitive proximity sensors, different sensor principles were evaluated.

An open-source rapid prototyping system, called OpenCapSense , was chosen as a base for a measuring system for the determination of the position of figer-sized objects. Due to the small size of the objects, an essential criterion for the quality of the measurements was the suppression of interferences. The implementation of shielding strategies reduces the effects of these interferences and at the same time achieves a higher symmetry for the capacity measurement.

Keywords: Capacitive proximity sensors, OpenCapSense, Schielding

February 11th, 2016

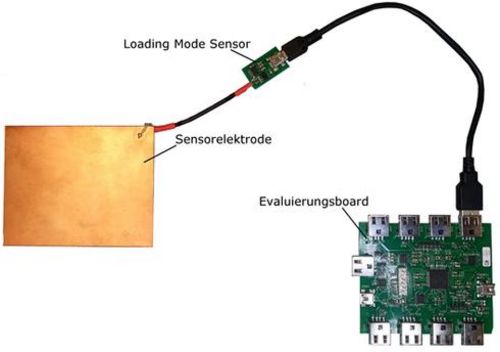

Figure 1: OpenCapSense (OCS) is a rapid prototyping system, which consists of an evaluation board, sensor and a sensing electrode.

Figure 1: OpenCapSense (OCS) is a rapid prototyping system, which consists of an evaluation board, sensor and a sensing electrode.

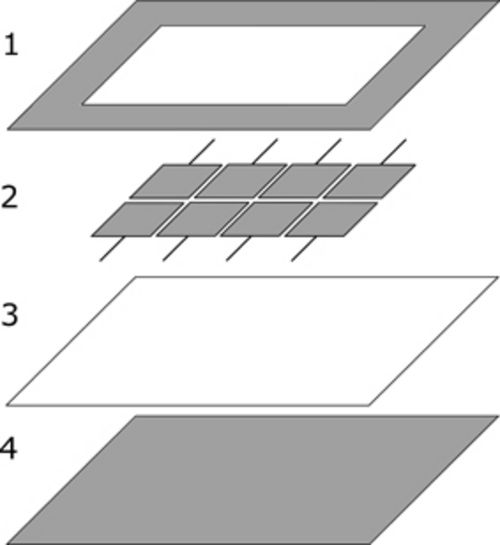

Figure 2: Sensor configuration consisting of contactshield (1), sensing elctrodes (2), layer of glass epoxy FR4 (3) and shieldelectrode (4).

Figure 2: Sensor configuration consisting of contactshield (1), sensing elctrodes (2), layer of glass epoxy FR4 (3) and shieldelectrode (4).