The research area "Composite Component Production" focuses on the production of continuous fibre reinforced thermoplastic composite components. As a basis for these components, we use so-called unidirectional (UD) fibre-reinforced tapes. The components are reinforced in a tailor-made way with these tapes in order to attain the required mechanical properties for the component with a minimum use of fibres.

In contrast to thermoset components, the use of thermoplastics offers the advantage of recyclability. This means that the plastic contained in the components can be recycled at the end of the product life cycle and does not have to be sent to landfill or thermal recycling. An additional advantage is the high degree of automation in production and the comparatively short cycle times in manufacturing.

The production cell consists of five sub-areas

1. Tape Laying: In the tape-laying cell, the pre-fabricated UD tapes are stacked on top of each other according to a previously calculated construction plan and spot-welded together. The result is a so-called tape stack, which has sufficient stability to be manipulated by a 6-axis robot.

2. Consolidation: The tape stack is first heated, pressed together under low pressure and cooled down to below the melt temperature of the polymer matrix. The result is a flat semi-finished product in which the individual tape layers are homogeneously bonded together.

3. Heating: The semi-finished product is heated in an infra-red (IR) furnace until the polymer matrix between the fibres is completely melted. The stability for the now following transport of the semi-finished product into the injection moulding machine is only given by the fibre content.

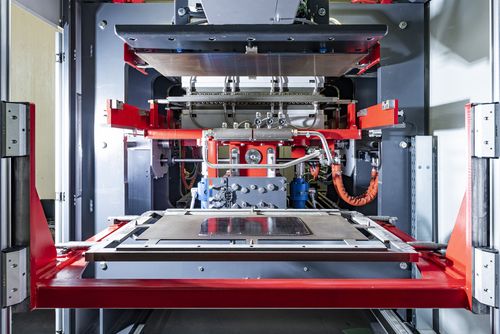

4. Forming and Functionalising: In the injection moulding machine, the quasi two-dimensional structure of the semi-finished product is transformed into a three-dimensional form when the mould is closed. The composite structure is then functionalised by back injection.

5. Automation: The component transport between the individual sub-areas or to the deposit conveyor belt is carried out by a 6-axis robot

DI Dr. Klaus Straka knows more about Composite Component Production

Fill - consolidation

Fill - consolidation

Organomelt - heating

Organomelt - heating

Demo tool - forming

Demo tool - forming