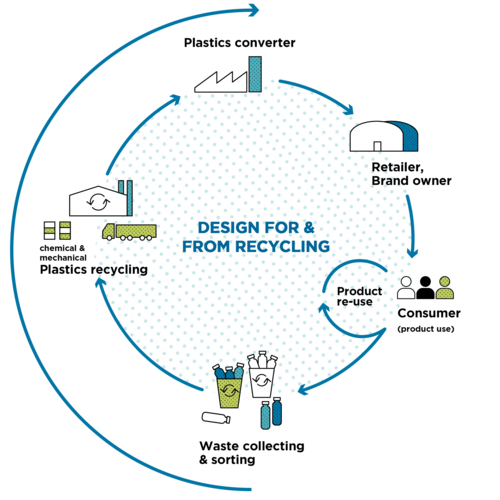

The JKU's LIT Factory has partnered with R-Cycle, opens an external URL in a new window. The initiative aims to, for example, document packaging properties during production in order to make this information available during the sorting and recycling process at the end of the product's life cycle. A new digital product passport contains the product's recycling-relevant information.

![[Translate to Englisch:] Frisbee Recycling](/fileadmin/_processed_/5/7/csm_Frisbee-Recycling-Grafik-jku-linz_e5b6fea5ba.png)

To make the concept more tangible, R-Cycle and the LIT Factory were showcased at K 2022, opens an external URL in a new window, the world's largest plastics trade fair. The basis is the JKU's internal recycling project titled "Space for Better Recycling".

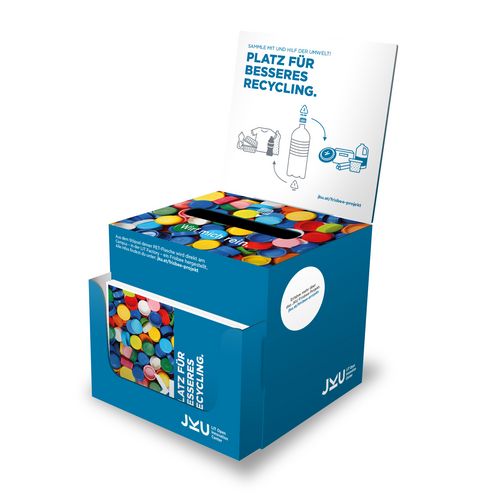

To promote more awareness about sustainable plastics, the LIT Factory started a program to get 103 classes at 19 schools in Upper Austria to collect bottle caps from PET beverage bottles. The high-density polyethylene (PE-HD) bottle caps have a recycling code of "2" and were then turned into cool frisbees at the LIT Factory. Students could also win one of many attractive prizes generously provided by our project partners.

1st Place: HAK Steyr - 4EK class, opens an external URL in a new window

2nd Place: HAK 1 Wels - 2DHK class, opens an external URL in a new window

3rd Place: HTL Andorf - 2AF class, opens an external URL in a new window

And a special award was presented to the Don Bosco Schule Vöcklabruck - 1 bafep class, opens an external URL in a new window

![[Translate to Englisch:] gewinner](/fileadmin/_processed_/8/0/csm_Gewinner_37c8ab4380.png)

Creating a frisbee requires several steps, starting with collecting the bottle caps. The recyclable materials need to be sorted, processed, shredded, undergo material analysis, and plastic recycling before the injection molding process ultimately creates a frisbee.

Once finished, the frisbee is given a JKU sticker and a QR code.

During the individual process steps, the systems and analyzers record the data to the product passport which can be accessed via the QR code.

Boxes to collect bottle caps were set up at schools throughout Upper Austria and students were given information about properly collecting materials. The students had one month to collect as many bottle caps as they could.

The sorting and processing procedure results in a single-variety PE-HD plastic grade fraction. Unusable metallic caps or bottle caps made out of other types of plastic are removed.

Once sorted and processed, the separated individual quantities collected from the schools were consolidated and processed collectively in a Lindner Micromat 1500 shredder, producing colorful, homegenously-sized plastic flakes.

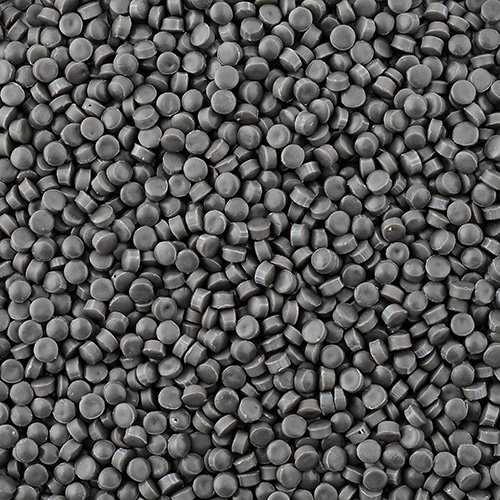

An Erema INTAREMA 1108 TVEplus machine turns the flakes into granules

The bottle caps are not sorted with regard to color so when the flakes are melted, the granulates formed in the recycling extruder yield a dark gray color.

The ENGEL duo 350 injection molding machine at the LIT Factory converts the recycled material into a new product, namely a frisbee.

The frisbees are given to newly enrolled students as part of the JKU's Welcome Week program, and are also available at the JKU Merchandise Shop .