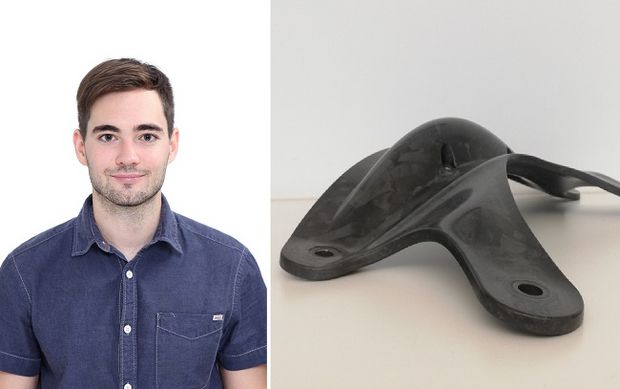

Cars made out of “scraps”: The automotive industry may soon be using recycled carbon fibers thanks to a new pressing method.

There is currently a move in production toward creating stress bearing components found in cars and airplanes out of fiber-reinforced plastics. Together with industrial project partners, researchers at the JKU want to go one step further and use recycled carbon fibers. The new method was presented at a current composites trade fair in the Stuttgart, "Composites Europe".

Stress-bearing structural components found in machines and airplanes are often made out of metal. While providing the required stability, the material can often be difficult and expensive to process. Attempts in recent years to make high-strength, lightweight components have led to creating methods to manufacture components made out of composite materials.

In many cases, industry – especially the automotive industry - is turning to the use of carbon fiber-reinforced plastics. These are fiber webs made into hard components by applying high pressure heat and adding resin. Philipp Stelzer (Institute of Polymer Product Engineering, JKU), explained to the APA, "These kinds of composite materials can be expensive to make. The fibers have to be completely pressed in to the mold and it take anywhere from several hours to several days to make a component."

In order to not only speed up the process but make it more cost-effective, researchers are using short, jumbled up pieces of fiber instead of continuous, neatly arranged fibers. Philipp Stelzer added, "This process is just now emerging and is not yet widely used in industry." Researchers in Linz, however, want to go one step further and use recycled fibers instead of new fiber pieces. Scientists are currently obtaining these scrap fibers from the aviation industry.

Philipp Stelzer remarked, "When using recycled fibers, the quality is naturally compromised. The challenge is to design the components so they meet the high standard requirements." Stelzer added that in addition to the component design, researchers have to address the question as to how the recycled material will be mixed with new materials and how – despite the poorly defined properties of the base materials – they can consistently achieve high quality. Stelzer emphasized that in the lab, researchers have already produced and tested a number of experimental components and the results are extremely promising.