Creep fatigue resistant materials for the power plant industry

Sustainable electrical energy production of the future will contain a balanced mix of photovoltaic, wind, biomass, geothermal, hydropower and eventually nuclear power plants. Within this wider context, plenty of material related challenges have to be tackled to guarantee energy production in Europe in the future.

Project Details

Seed Project

Project Leader

Bernhard Sonderegger

Call

10/2021

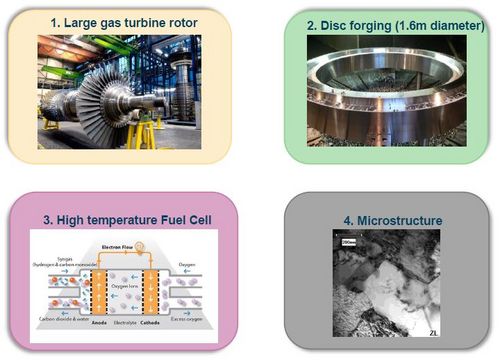

Due to the fluctuating energy output of wind and solar, their production must be compensated by intelligent grid design, energy storage and other power plant types. Gas- and steam power plants qualify for this task, since, in principle, they can be refurbished to run with hydrogen (gas) or biomass (steam). However, the mechanical load within the components will shift from pure creep to creepfatigue. Conventional creep resistant materials do not automatically qualify for creep-fatigue loads.

The project deals with testing an established physically based creep model for creep-fatigue conditions. The model is extremely flexible and considers the current material state by modelling the microstructure evolution and linking it to actual deformation rates. The model is further flexible with respect to temperature- and stress changes. However, highquality experimental data (creep/creepfatigue curves, microstructure data) are necessary for demonstrating the applicability of the model to the more complex loading conditions. These data are now provided by the collaboration partners of the project. With the help of the Seed funding, we aim at raising the TRL (technology readiness level) from 3 to 4. We consider level 4 to be sufficient to apply for a follow-up CDlaboratory.

Univ.-Prof. DI Dr. Sonderegger conducts research in the field of materials science as part of the triad between applied mechanical engineering, base-knowledge physics, and numerical methods in mathematics and computer sciences. He earned his academic degrees at the Graz University of Technology where he also worked several years. Before moving to JKU in 2020 he was head of the Testing and Microscopy Department at the MPA Stuttgart. In 2013/14 he was a professor at the University of Cape Town and a Schrödinger fellowship once took him to Denmark University of Technology. In teaching, Prof. Sonderegger sees educators as team mebers for the common goal of successfully completing a degree program.