The Locomotion Lab focuses on motion analysis and personalized technologies. We are looking for individual, mobile and lightweight solutions that can seamlessly interact with human movement in the fields of health, medicine, sport and entertainment. We are conducting research into new product development methods, exoskeletons, mobile robotics applications involving drones and new manufacturing processes to facilitate these applications.

DI Dr. Martin Reiter and DI Jakob Ziegler understand more about Locomotion Lab

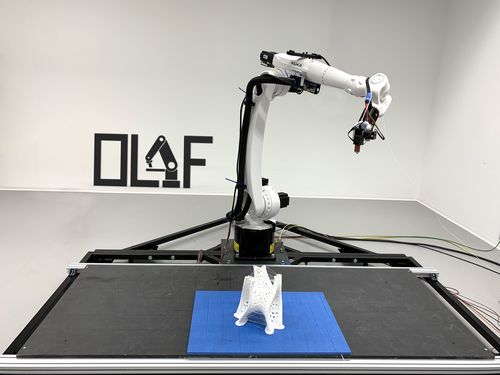

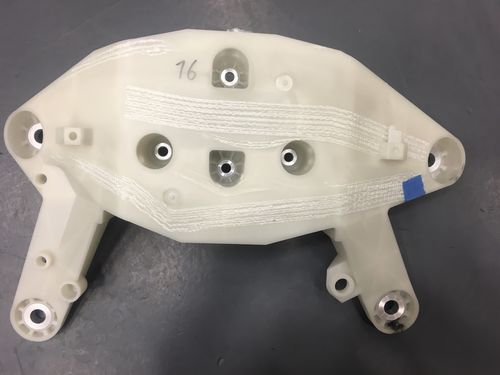

In the future, individualized technologies will dominate our everyday lives to an ever greater extent. Especially in the fields of medicine and health, tailor-made solutions are an intrinsic necessity. The key to delivering on this vision of the future is fast, fully automated 3D printing processes. This is why this laboratory focuses on developing and implementing new robot-assisted printing processes facilitating relatively large individualized components to be produced using lightweight construction methods. In addition, there is an option to produce a wide variety of materials during a single printing process, or even integrate electronic components during the printing process.

One of the biggest advantages of continuous fiber-reinforced materials lies in the rapid market growth of composite components (such as carbon or glass fiber composites). Producing these types of components is, however, very time-consuming and cost-intensive. Costs could be reduced to a large extent by only incorporating fibers in the part where they are actually needed. This is why we have devised a process to enable precise placement of continuous fibers in the direction of loading. To this end, fiber strands that have been impregnated with a thermoplastic matrix are manufactured using a 6-axis robot in the form of a complex 3D structure. Subsequently, these fiber constructs can be inserted into a conventional injection molding process in order to reinforce a component at the critical areas while simultaneously utilizing the advantages of the injection molding process.

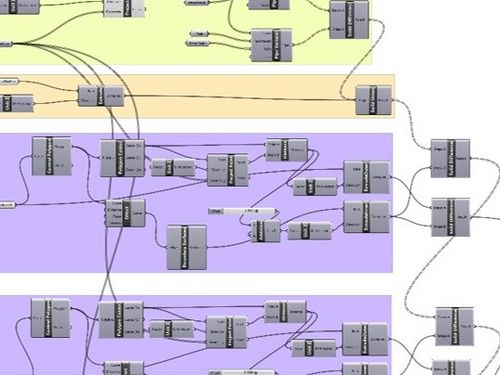

New manufacturing processes inevitably also require new methods of component design and implementation based on the computer-aided manufacturing process. This is why we are also constantly working on new product development methods in close cooperation with process development. These methods consist of theoretical approaches and guidelines as well as new software tools to enable both automated component design and automated production.

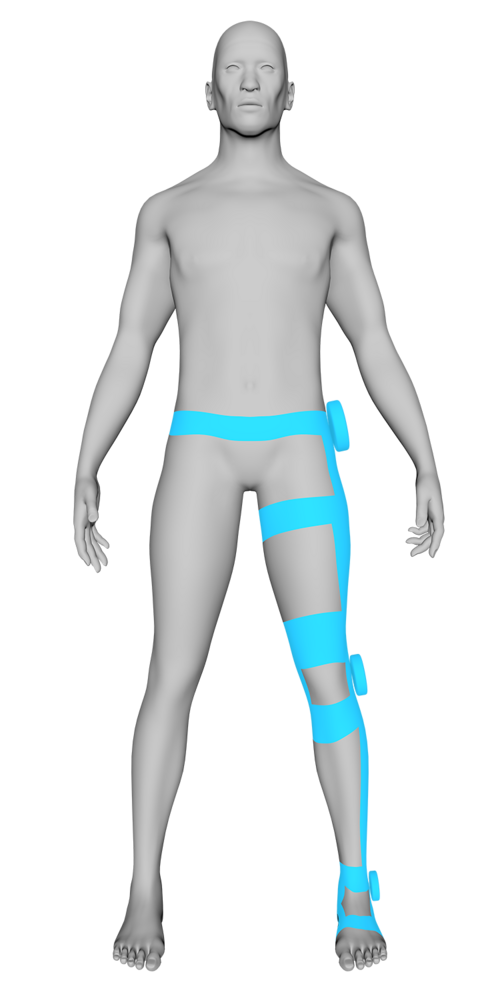

An ageing society worldwide is coupled with an ever-increasing need for motion support systems and rehabilitating impaired movement. To supplement conventional technologies and therapy methods, robotics are becoming increasingly important in medicine and biomechanics. The Locomotion Lab analyzes human movement by using a motion capture system to create active prostheses, orthoses and exoskeletons designed to support - and even enable - mobility.

We are also conducting research into innovative rehabilitation system, such as robotic hippotherapy, i.e. imitating horseback riding by using a robot, in order to treat stroke patients, for example.

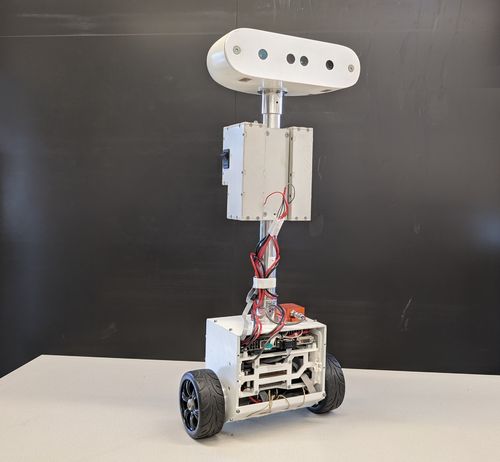

We have structured our environment in accordance to our abilities. A humanoid robot, for example, has been modeled based on the human form, imitating the way we move so they can integrate better into the human environment, increasing in flexibility in areas where conventional robots are limited by doors and stairs. We analyze natural motion sequences, conduct research on bipedal movement, study the way humans interact with machines, and devise new control mechanisms.

We encounter mobile robotics everywhere on a daily basis with applications ranging from lawn mowers and vacuum robots, to the use of autonomous vehicles. Our research spans topics such as the dynamic modeling of non-holonomic systems (such as a Segway), the ideal kinematics of redundant systems, autonomous navigation, and human-robot collaboration within industrial environments. We are developing and researching driverless transportation systems to support logistics, mobile obstacles to support test scenarios in the automotive industry, and autonomous drone piloting.