The EREMA Intarema series recycling machines are considerably large. The Intarema plastic recycling machine at the LIT Factory is approx. 20 meters in length.

The systems, however, can be considerably larger and several stories high. Until recently, a centrally located static control panel was used to operate recycling plants. In an effort to support ideal settings and optimize and commission non-centrally located plant sections, one must refer to the central operating panel.

The EREMA recycling machine in the LIT Factory

The EREMA recycling machine in the LIT Factory

The Intarema machine at the LIT Factory now has a wireless mobile panel made by SIGMATEK.

The advantage is being able to commission and program settings directly on the corresponding machine section with an outlook on the process. HGW 1033 is a handheld, wireless control unit featuring a 10.1 “capacitive multi-touch display with an approval button, key switch and active, illuminated emergency stop".

The HGW 1033 base station, BWH 001, is centrally attached below the machine control panel. BWH 001 serves as a docking / charging station and provides an WLAN access point to support the wireless control unit.

With the wireless handheld control unit, the machine operator can get very close to the relevant machine or system part

With the wireless handheld control unit, the machine operator can get very close to the relevant machine or system part

To pair the HGW 1033 unit with the base station, a blink code generated by the tower light on the base station must be confirmed on the operating device. This ensures that the operator is within range of the base station during safety-related pairing. Once successfully paired, the emergency stop button will light up and the machine's individual number will be displayed.

The machine's central operating panel displays all of the important screen pages on the wireless safety panel, meaning that the operator can carry out all of the functions and setting measures anywhere on the machine.

Should a critical safety situation occur, the machine can be switched to a safe state by using the integrated EMERGENCY STOP at any time and from anywhere on the machine.

The central control panel of the EREMA machine and below the wireless handheld control unit from SIGMATEK

The central control panel of the EREMA machine and below the wireless handheld control unit from SIGMATEK

The HGW 1033 unit communicates with the BWH 001 base station via two redundant WLAN connections (2.4 / 5 GHz).

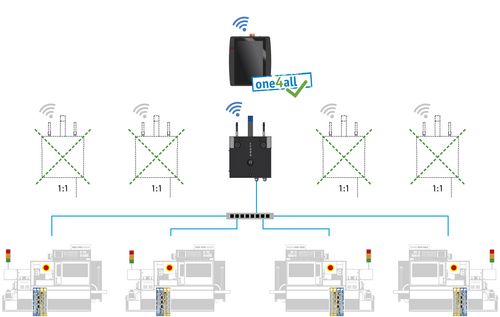

Standardized OPC UA protocol supports communication with the Siemens machine control. The wireless, battery-operated, handheld control unit can run continuously for 2 hours. Very large systems can contain several base stations. The concept is advantageous in that as the system grows, the system operation costs are proportionately reduced.

Please contact DI (FH) Bernd Hildebrandt - Sigmatek, opens an external URL in a new window to learn more.

Just one wireless HMI and one base station can operation several machines or system parts.

Just one wireless HMI and one base station can operation several machines or system parts.

Sigmatek's HGW 1033 offers safety to go and a friendly user experience

Sigmatek's HGW 1033 offers safety to go and a friendly user experience